METAL SHELVING AND STORAGE SOLUTIONS

PRICES

Factory direct

QUOTES

No obligation

PAYMENTS

100% secure

PERSONALIZED

service

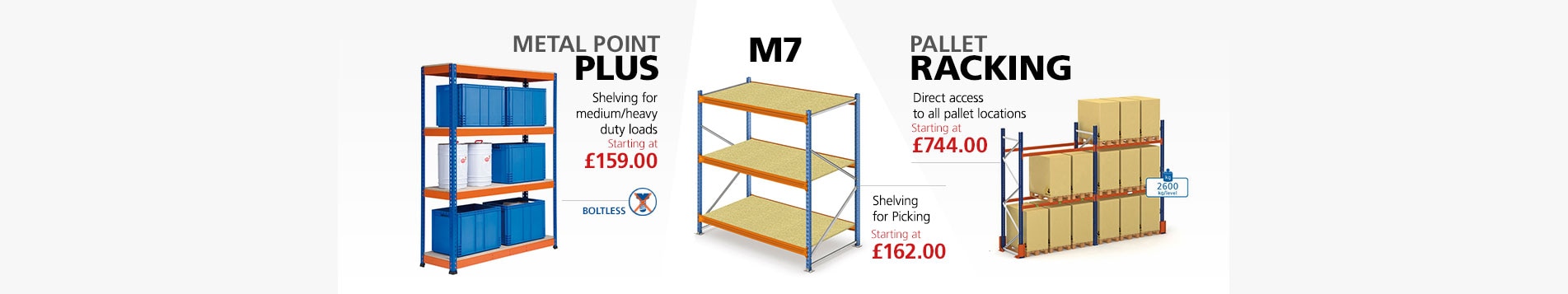

Heavy Duty Shelving & Racking

HIGH QUALITY METAL RACKING AND SHELVING

Quality is the unmistakable hallmark of Mecalux, and metal racking and shelving are our speciality. Whether used for light or heavy loads, our models are fully configurable to meet customers’ needs.

For picking operations, Metal Point shelving is a clear reference in the market. It is very easy to assemble, thanks to its boltless design. In addition, it is extremely safe, made in accordance with the most demanding standards in the market. This system can support up to 600 kg per level.

We also have slotted angle shelving. This simple, economic solution holds up to 140 kg per level, making it ideal for light-duty loads and small objects. And for offices, the perfect solution is our Shelving M3, with side panels and metal doors.

For heavier loads, we have pallet racking with a capacity of up to 3,000 kg per level. It is the best option on the market for your factory or warehouse, thanks to its high resistance and the wide variety of configuration options. With our racking and shelving solutions, you can rest assured that your goods will always be in good hands.

Light & Medium Duty Shelving

STORAGE AND ORGANISATION SPECIALISTS

At Mecalux, order and storage are paramount. Therefore, apart from our extensive catalogue of racks, we manufacture other products, such as: work benches, metal lockers for changing rooms and work tables.

LOGISMARKET: ADVANTAGES GALORE

It is very easy to make purchases in Logismarket. Choose the product you want, add it to the shopping cart, complete the shipping information and select the payment method. You will receive your order in just a few days. Just like that.

For large orders or special measurements, feel free to contact us for a personalised quote.

As for shipment, there are several available options. We can deliver your order directly to your home or business, or you can pick it up at no charge at any of our warehouses in the UK.

Our customers are what matters most. Therefore, our Customer Service team is prepared to answer any questions you have about our products or the purchasing process.

We also encourage you to register with our website. This way, you can receive personalised offers and, in the event of a purchase, track the status of your order in detail.

CONTACT ONE OF OUR SALES REPS • PERSONALIZED SERVICE

Tell us what you need and we will find the most effective solution

Request information and/or a quoteRECEIVE OUR NEWSLETTER

Sign up to find out about all our new developments and exclusive promotions